Introduction

In Part I of this three-part series, differential and common modes on RF transmission lines were defined and discussed.

In Part II of this article, the work of Gustav Guanella was chronicled, followed by Joe Reisert’s improvements to Guanella’s original design. The construction of a common mode choke was presented that included data for the coax used. Finally, some analyses were performed that predicted the performance of two common mode chokes. Graphical results were reported.

In this final Part III, the results of measurements performed on two common mode chokes are presented: one for 2 x FT240-31 stacked ferrite cores and another for 2 x FT240-43 stacked ferrite cores. Due to its higher initial permeability, it was expected that low-frequency choking performance for the 2 x FT240-31 material would be superior to that of the 2 x FT240-43 material. We found that this was not the case for the single sample of 2 x FT240-31.

Discussion

Two coaxial line chokes were constructed to suppress common mode currents on transmission lines. Common mode currents are apt to find their way back to the operating location on the coax shield. Common mode currents can create performance problems in the form of added receiver noise and operator problems in the form of RF bites. The choking impedance should be located at a voltage node in the feedline where the wave impedance of the standing wave is low.

The coaxial line chokes were constructed on stacked cores of FT240-31 and FT240-43 material, as the literature recommends both for EMI suppression. Eleven turns of RG-400/U coax were wound on each of the stacked cores with the Joe Reisert, W1JR, crossover winding located in the center. Each choke was housed in a connectorized Bud Industries PN-1323 box. The common mode rejection for each choke was measured with a spectrum analyzer over a 1.8 to 29.7 MHz bandwidth. The spectrum analyzer tracking generator output was split into two in-phase signals that fed the choke coax center conductor and the choke coax braid in true common mode. The resistive divider formed with two 25.5-ohm resistors (made with 51-ohm resistors in parallel) is shown in Figure 1. The divider was fed in the center by the tracking generator and the ends of the 25.5-ohm resistors fed the center conductor of the coaxial connector and the connector shell. There was a similar arrangement at the output so that the spectrum analyzer could measure the resulting common mode rejection. The conduction path of the test cable shield was carried from input to output on #16 AWG as shown. Figure 2 shows the device under test. Some undesired responses were due to some nearby equipment, coax and line cords. The distance between the test coax shields also presents some challenges, and an interconnection bridge is shown that consists of a rather long piece of #16 AWG wire. After moving some cables, line cords, and equipment around, some useful data was collected. Figure 1 – Feeding the Common Mode Choke in Common Mode. A resistive power divider was constructed that consisted of paralleled 51-ohm resistors to make two 25.5-ohm resistors. The center conductor of the choke coax and the choke coax shield were fed with in-phase signals from the spectrum analyzer tracking generator.

Figure 1 – Feeding the Common Mode Choke in Common Mode. A resistive power divider was constructed that consisted of paralleled 51-ohm resistors to make two 25.5-ohm resistors. The center conductor of the choke coax and the choke coax shield were fed with in-phase signals from the spectrum analyzer tracking generator. Figure 2 – Recombining the Common Mode Signals. Similarly, a resistive power combiner was constructed at the choke output that consisted of paralleled 51-ohm resistors to make two 25.5-ohm resistors. The in-phase signals from the center conductor of the choke coax and the choke coax shield are recombined and fed to the spectrum analyzer input. The shield from the input coax and output coax is bridged with a piece of #16 AWG copper wire as shown.

Figure 2 – Recombining the Common Mode Signals. Similarly, a resistive power combiner was constructed at the choke output that consisted of paralleled 51-ohm resistors to make two 25.5-ohm resistors. The in-phase signals from the center conductor of the choke coax and the choke coax shield are recombined and fed to the spectrum analyzer input. The shield from the input coax and output coax is bridged with a piece of #16 AWG copper wire as shown.

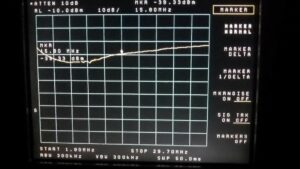

The reference level of the spectrum analyzer was set for -10 dBm and all measurements were made relative to that level. The first screenshot is for 11 turns of RG-400/U wound on 2 x FT240-31, while the second screenshot is for 11 turns of RG-400/U wound on 2 x FT240-43 material. Since the toroids are wrapped with the same number of turns of RG-400/U, the #31 material, possessing higher initial permeability, is expected to exhibit a higher choking impedance at 1.8 MHz than the 43 material. This does not appear to be the case for this batch of #31 ferrite. The provenance of the #31 material is good. In any event, there is greater than 20 dB of common mode rejection for both ferrite types from 1.8 to 29.7 MHz. While the response appears to favor low frequencies for #31, the overall suppression is better for this batch of #43 material. No loss corrections have been made for the resistive power divider or resistive power combiner. Figure -. Suppression of a 2 x FT240-31 Line Choke. The ferrite material favors the lower bands but the overall suppression is inferior when compared to that of the 2 x FT240-43 line choke. Deconstruction of the choke may disclose some defects in materials or construction. Only a single choke of this type was constructed.

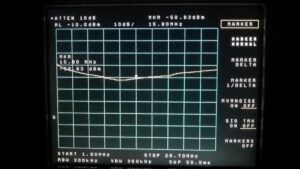

Figure -. Suppression of a 2 x FT240-31 Line Choke. The ferrite material favors the lower bands but the overall suppression is inferior when compared to that of the 2 x FT240-43 line choke. Deconstruction of the choke may disclose some defects in materials or construction. Only a single choke of this type was constructed. Figure 4 – Suppression of a 2 x FT240-43 Line Choke. The ferrite material favors the higher bands but the overall suppression is superior when compared to that of the 2 x FT240-31 line choke. Fortuitously, several chokes of this type were constructed.

Figure 4 – Suppression of a 2 x FT240-43 Line Choke. The ferrite material favors the higher bands but the overall suppression is superior when compared to that of the 2 x FT240-31 line choke. Fortuitously, several chokes of this type were constructed.

Conclusions

A single choke was constructed with FT240-31 material while several were constructed with FT240-43 material because most of our operation is above 7 MHz. While the shape of the response appears to favor low frequencies for #31, the overall suppression is far greater for this batch of #43 material. These measurements will be repeated when another batch of FT240-31 material is obtained. Furthermore, it is possible that the deconstruction of the FT240-31 choke may disclose some construction or material defect.

No comments:

Post a Comment